Friday, 20 December 2013

Documentation

When your system is fully installed, documents have to be issued.

We have the technical documentation & user documentation. You can think of them as manuals. Detailed information about a system's design specifications, its internal working & its functionality are found in documentation.

* User Documentation: It is provided to users to help them operate the newly implemented system. It can also take the form of a tutorial.

* Technical Documentation: It is provided specifically for the systems analyst & the programmer to help them in further upgrading & improvements

1st: The user documentation is issued to familiarize the system & its various components to the user who have no idea on how to operate it. It also saves the analyst's time, as if the documentation is effective, he/she won't be contacted on a regular basis. The user documentation includes:-

- Screenshots as well as descriptions regarding the operation of the system.

- Purpose of the system

- Input & output formats and what to do when errors arise.

- Hardware & software needed

- Troubleshooting guides and a list of FAQs

The technical documentation is also split into two parts:-

* System Documentation: It provides a detailed overview of the whole system. It includes:-

- Test plans & test results

- Results of system analysis (including elements such as DFDs)

- What is expected from the system

- Overall design decisions such as the choice of hardware and/or software.

* Program Documentation: It is produced for the pieces of program code that have been written. It includes:-

- A description and the purpose of the software.

- The input & output data formats that have been used.

- Program flowcharts that were produced.

- The program listing

--- This will help any future programmer to make modifications to the system ---

- A description and the purpose of the software.

- The input & output data formats that have been used.

- Program flowcharts that were produced.

- The program listing

--- This will help any future programmer to make modifications to the system ---

Saturday, 30 November 2013

Friday, 22 November 2013

ISBN Calculations (Check Digit)

During the design stage, the designer has to limit the chances of inaccurate data. Therefore, validation checks have to be established. These checks include:-

1) Range Check: Checks whether data is within acceptable boundaries.

2 ) Length Check: Checks if the data is entered with the required number of characters

3) Character Check: Checks that the data entered doesn't include invalid characters

4) Picture Check: Checks that data is entered in a specific format.

5) Limit Check: Similar to "Range Check", only it has one boundary.

6) Presence Check: Checks that data is actually present.

7) Consistency Check: Checks that data field tie up with each other

8) Check Digit: Performs complex calculations on a range of numbers, then compares them with the check digit. (We'll go into this more deeply with the ISBN calculations)

- Take the first 12 digits of the 13-digit ISBN

- Multiply each number in turn, from left to right by a number. The first digit is multiplied by 1, the second by 3, the third by 1 gain, the fourth by 3 again, and so on to the eleventh which is multiplied by 1 and the twelfth by 3.

- Add all of the 12 answers.

- Do a modulo 10 division on the result from step 2. (Don't know what a modulo 10 division is? It's easy. It's just the remainder from a whole number division by 10. I bet you learned to do that in junior school, before you even learned about decimal fractions.)

- Take that remainder result from step 4.If it's a zero, then the check digit is zero. If the remainders isn't zero then subtract the remainder from 10. The answer to that is your check digit.

Let's take #9781861972712# as an example:-

9 x 1 = 9 7 x 3 = 21 8 x 1 = 8 1 x 3 = 3 8 x 1 = 8 6 x 3 = 18 1 x 1 = 1 9 x 3 = 27 7 x 1 = 7 2 x 3 = 6 7 x 1 = 7 1 x 3 = 3

Add the results

9 + 21 + 8 + 3 + 8 + 18 + 1 + 27 + 7 + 6 + 7 + 3 = 118

Modulo 10 the result

118 modulo 10 = 110 remainder 8

Work out the digit

8 doesn't equal zero, so check digit = 10 - 8 = 2

Evaluation

There, the system has been fully installed and it's up & running. The users of the system are to evaluate the system. During this stage, two key questions will be asked:-

Q1) Does the finished solution meet its requirements?

Q2) Does it solve the problem?

What's the point of a solution which doesn't solve its corresponding problem? Nothin' right? So when these key questions are answered positively, then the system has succeeded. If otherwise, then it was a waste of time & resources.

Further to those two questions, the evaluation considers:-

* Lessons learnt from the problems encountered, so the next project will be even smoother & successful.

* Any maintenance and support needed in day-to-day running of the system

By now, the analyst will have determined the success of the new system, that is by getting feedback from the users. He will also have seen if the users are satisfied. He will have recorded the extensions suggested to the system based on the users' opinions. This gives him a clear idea about the limitation of the system.

Once these limitations have been identified, the analyst now has to interview the users and collect their opinions, suggestions regarding the limitations and further extensions. They will have to decide whether the good features of the system can compensate for these extensions. If not, then the analyst will have to analyze the new system and see where the extensions should be included. The system life cycle goes on...

Implentation

At this point, the system is designed, tested and is ready to be implement it. The thing is, how to do so? Knowing that there are four ways in which you can implement the system. So, which one is the best choice? Like with the methods of recording info back in the analysis stage, there is no black & white rather than it's all shades of grey.

1) Parallel Running: Both the old & the new system will work simultaneously and then the new system gradually dominates.

* Pros: Workers can be trained to use the new system while it is being implemented. If there are any problems with the new system and it has to halt, the old system will still be there as a backup.

* Cons: Two sets of workers have to be paid to keep both systems running. It takes a lot of time to be fully implemented. Actually, it is the slowest method of implementation.

2) Phased Implementation: Implementing the system one part at a time. This is like buying a fixed asset with monthly payments (Hire Purchase).

* Pros: If one aspect of the system fails, the other aspects will remain unaffected. Workers will have time to get used to the new system.

* Cons: It is a slower method when compared to direct changeover. If the new system fails, there's no hope to revert to its predecessor.

3) Direct Changeover: From the name itself, the old system is replaced instantly with the new system.

* Pros: Only one set of workers have to be paid, so it doesn't cost as much as in parallel running where two sets have to be paid. It's the quickest way to fully implement a new system.

* Cons: No backup is there. So if the new system fails, you're done for. It can be difficult to make improvements to the new system and keep it working.

4) Pilot Running: The system is implemented in one branch of the organization whilst the other branches carry out with their existing one.

* Pros: If the system doesn't work properly, the other branches won't be affected. The later branches benefit from the mistakes made in earlier branches.

* Cons: It is a slow method of implementation.

Development & Testing

The data structures are now designed and now we can move on to the next stage. Let's start with "development". After the data structures have been designed, it's time to create them using the software or programming language recommended by the analyst.

Now that the system is created, what if things don't work out. What if the created system failed to meet it's goals. One thing for sure, it won't look good in the programmer's resumé. This is why the system has to be tested thoroughly before being implemented. So, how to test it?

First of all, a test plan has to be produced by the analyst. This plan will contain the test data and the expected ones to be produced by the system. The analyst will then note the 'actual' data. Those data or the ones 'actually' produced by the system. The analyst will also make comments on the data produced and how they differ from the expected results.

Going deep into test data, it is of three types:-

1) Normal Data: The data valid & acceptable by the system.

2) Abnormal Data: The data invalid & rejected by the system.

3) Extreme Data: Note that this type of test data is only found where a range of data is input. Extreme data is the either the maximum or minimum data.

Don't go anywhere, just not yet. There is another way of testing a system and that is by using the live data. This is the data that has been used in the existing system, It will be used because the outputs are already known.

Design Stage

Now that the analyst as all of the information needed recorded, it's the designer's turn. The designer will have to design the inputs & outputs of the system, database stores, process of the system, validation check and test data for the system.

However, the designer has to keep in mind several factors when designing the new system. He has to consider:-

1) The fluency and smoothness of the system, i.e. it should be easy to use, navigate through and not over-elaborate.

2) A ship won't sail without its captain. The new system has to contain guidelines & instructions and should be free of misleading figures.

3) The margin of error is so small and therefore, the designer should be well aware of them and has to limit the possibility of inaccurate data.

Imagine what would happen to the user if he found the system without these factors. He/She will definitely get a short-circuit & blow their fuses.

The format of the output can take various shapes, from which includes: graphs, reports, list of records and tables. The output can be produced on paper, on screen display and/or sound display.

* Why do you think sound display is an option over here?

There will be two files to be designed:-

1. Master file: This contains data which do not often change such as name, date of birth, gender, etc...

2. Transaction file: This one contains data which change often such hours worked, phone number(s), etc...

How to reduce errors? Can you think of a way to reduce them apart from validation? There are more ways around a door than a key. As a matter of fact, there are several ways in which you can do this:-

1) You can use the coding method to make the character length shortened. If you're not familiar with this method, coding is more like replacing an entire data with a letter or symbol. For example, you can write "Male" as "M" and "Female" as "F", "Yes" with a tick and "No" with a cross.

2) Alternatively, you can use direct input data. The next time you visit a supermarket, check the barcode on a product and how does the cashier use the POS (Point of Sale) to directly input the data to his computer. Scan the barcode and you're done, it's as simple as that.

System Analysis

So before anything happens to your system, it has to be analysed. This is the first stage of the SLC, analysis stage. To be clear & simple, system analysis means examining the existing system in detail.

There are four main & distinct ways to collect information:-

1. Examining of Paper Documents

2. Interview

3. Questionnaires

4. Observation

The pros & cons of each can be seen from this table:-

Now, which is the most effective method? Well actually, we can't judge by their names or functions. Judging the effectiveness of any of these methods depends on the situation.

Like for instance, a receptionist may be too busy to interview, so in this case you'd go for observation. In a case of a manager, you would like to probe for more feedback, more info, more stuff. Therefore, an interview would fit the bill.

If you have a large number of people, like employees or customers, would you choose to observe or interview. If you chose either, then you made a mistake. You can't interview or observe hundreds of thousands employees, can you? No, therefore questionnaires are most suitable where you can copy a lot of those questionnaires and send them to the workers.

Sometimes, none of the three methods above would give you an exact detail of a particular aspect. Let's say, the transaction details. The manager would not tell you those kind of details. For that, examining of papers is the method. You can refer to those papers to view all the transactions, the accounts, etc... .

Monday, 28 October 2013

Using Spreadsheets

Okay, so now you have a list of data recorded and saved as a CSV file and you want it as a spreadsheet. First of all, you've got to know a bit (or a lot) more about them before doing anything. So first things first.

1) What is Spreadsheets Modelling?

Spreadsheet Modelling is a computer program that allows you to create, edit and maintain full data. Note that the output depends on the input. Changing the input value will most certainly affect the output.

2) List three uses of Spreadsheets.

So you're wondering what those spreadsheets can do? Well, you can put it this way: It is used to design, perform calculations, produce high quality output; the fact is that it is actually used to predict the possible outcomes

3) What does CSV.File stand for.

You should be very aware that CSV stands for "Comma Separated Values". Forget this and see where that'll get you.

1) What is Spreadsheets Modelling?

Spreadsheet Modelling is a computer program that allows you to create, edit and maintain full data. Note that the output depends on the input. Changing the input value will most certainly affect the output.

2) List three uses of Spreadsheets.

So you're wondering what those spreadsheets can do? Well, you can put it this way: It is used to design, perform calculations, produce high quality output; the fact is that it is actually used to predict the possible outcomes

3) What does CSV.File stand for.

You should be very aware that CSV stands for "Comma Separated Values". Forget this and see where that'll get you.

Saturday, 19 October 2013

Friday, 18 October 2013

System Design (Home-Work Question)

When desigining a layout, the analyst will be influenced by the views of the users and their requirements. He'll need to consider who will see them. There will also need to be consultation with the owner(s) of the firm.

For screen forms, the analyst has to consider the attractiveness of the screen layout and its simplicity. The screen form should not be complicated for the users and it is heavily advised to include on-screen instructions on how to navigate from screen to screen.

The main aspects of the way output is designed is its output and the medium it is to be produced on.

The format could be: graphs, tables, reports or lists of records. The medium on the other hand could be a hardcopy (paper), a softcopy (screen display) and/or sound.

Sometimes, the designer will also want to consult customers via questionnaires in order to design the most suitable system for the firm. It is normal for system analysts to produce three or four different designs of an item output. When designing these, the analyst is fully aware of what the purposed system is capable of producing. The users of the system will also be asked for their views.

For screen forms, the analyst has to consider the attractiveness of the screen layout and its simplicity. The screen form should not be complicated for the users and it is heavily advised to include on-screen instructions on how to navigate from screen to screen.

The main aspects of the way output is designed is its output and the medium it is to be produced on.

The format could be: graphs, tables, reports or lists of records. The medium on the other hand could be a hardcopy (paper), a softcopy (screen display) and/or sound.

Sometimes, the designer will also want to consult customers via questionnaires in order to design the most suitable system for the firm. It is normal for system analysts to produce three or four different designs of an item output. When designing these, the analyst is fully aware of what the purposed system is capable of producing. The users of the system will also be asked for their views.

Tuesday, 21 May 2013

Using ICT in Project Management

Use of ICT in Project Management

_______________________________________

Why is it needed?

Time is the most important element and the one in shortest supply. For any project, it is essential that a business has to plan for it. Projects include: construction of a new building, designing an aircraft, starting up a business, etc... Would you imagine how carrying out the process would be if they were not planned?

How to manage a project?

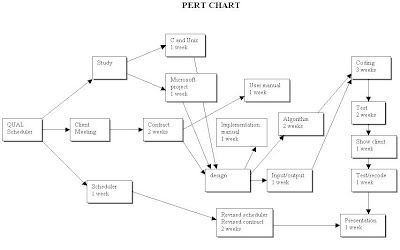

There're simple applications which could be used for project management but there're sophisticated software's which are used for the purpose. However, the most popular tools now-a-days are the Gamtt & Pert Charts.

A PERT chart is a project management tool used to schedule, organize, and coordinate tasks within a project. PERT stands for Program Evaluation Review Technique, a methodology developed by the U.S. Navy in the 1950s to manage the Polaris submarine missile program.

A Gantt chart is a type of bar chart, developed by Henry Gantt in the 1910s, that illustrates a project schedule. Gantt charts illustrate the start and finish dates of the terminal elements and summary elements of a project.Some Gantt charts also show the dependency (i.e. precedence network) relationships between activities. Gantt charts can be used to show current schedule status using percent-complete shadings and a vertical "TODAY" line as shown here.

Wednesday, 27 March 2013

Stock Control

Stock Control

What is Stock Control?

Stock Control is the system which monitors the items in stock. Should the store run low on items, re-ordering is required.

Note that too much stock is not good for the store; nor too little is. This is due to several facts including:-

* Too much stock costs more money. Keeping too much stock could lead to 'stock overload'

* Storing a lot of perishable items such as food is not a good idea as these items are going to perish sooner or later.

* Having too little stock means that the store is going to run out of stock before the next delivery times.

Point-of-sale (POS) is the place where items are retailed and all transactions are made. Refunds are also done there. A POS consists of a screen, a barocde reader & a number pad (should the barcode reader goes out of order. A normal POS is called as the manual system as it doesn't keep track of stock constantly. It is not connected to a database over a netowork and hence re-ordering and update take place manually.

An Electronic Point-of-sale on the other hand is known as the automatic system. It pretty much consists of the same components as the normal POS. The only difference is that the EPOS is connected with a database. This means that most of the things are done automatically.

The whole process of the EPOS has some benefits to both the super markets & the customers. They involve:-

- Goods are re-ordered automatically when stock falls under the the re-order level.

- Stock is updated after each transaction leading to a more accurate idea of stock levels.

- Questions over the bill can be resolved in a blink of an eye as a result of the itemized bill

- The use o f barcodes ensure greater accuracy and reduce errors.

In old times, retailing stores used to go counting the items in stock and ordering a large amount of items from the wholesalers. This done annually. The problems arises from the financial point of view as the company or supermarkets have to pay a substantial amount of money for the warehouse facilities and employees. Hopefully, the 'just-in-time' solves this issue as it ensures items to be delivered right where and when the company needs them.

Tuesday, 5 March 2013

Impact of ICT on Working Practices

Impact of ICT on Working Practices

ICT has changed the world enormously in many different ways. People used to send written letters and it would take months to reach to the recieving party but today e-mails are used to deliver instant messages. From the social aspect, ICT has changed the way people used to communicate as it has introduced social netwroking sites to the world. But lets not forget on the working practices as well.

Q) How do workers experience this?

Workers' premises has been altered and made more flexible. Workers can work remotely from home or anywhere away from their workplace. They can connect to their work's database via Virtual Private Network (VPN). This is a secure connection between the worker's PC/laptop and the company's network.

Q) How the working practices are different from the past?

Past: In the past, written documents were very common. Companies used to have a whole room for storing files. Those rooms were called as the "Registries". Companies also had to employ typists.When companies receive letters as written documents, typists would type them using a typewrite.

Today: Today, files are stored as digital format in small few hard disks and can be accessed by more than one person per time. Even documents can be word processed by clerks who can edit these documents effectively.

ICT has made the world more efficient than before and work can be achieved much faster and effectively.

Teleworking

Teleworking

People have been working in their workplaces every working day and earn their salaries monthly. But there have been times when an employee cannot attend his/her workplace because of certain circumstances such as falling ill or looking after a baby. When they were incapable of coming to work, they weren't able to do their work and hence have a lot to catch up.

Today, we don't have that problem since teleworking has become common. Teleworking: Employment in home while communicating with the workplace such as a company, bank, etc... using a phone, fax, modem, etc...

With the availability of technology tools such as the internet, workers are able to work with the presence of family with the worker's home. The employee does his work from home, his manager keeps a constant check on him to make sure that the work is being done. The worker then submits his work on a specific time to the workplace. However, some employee don't recommend working from home as they don't trust themselves whether they'll manage their time well or not.

Q) What is Remote Work?

Remote Work is when someone works away from office such as a professorial going down to the petrol extraction field. He then has to report back to the workplace wirelessly. This is known as Remote Working. Another example is a case in which a doctor has to visit his patient. He'll check the situation and checks the hospital database remotely.

Q) What is a Home Based Work?

Home Based work is the usual work that is done by the workers & managers in their workplace. An obvious example is a teacher teaching in school.

Saturday, 23 February 2013

Air Conditioning

Air Conditioning

What is "Air Conditioning"?

Air Conditioning means controlling and altering the condition of air by means of cooling, heating, disenfecting, etc... to more favourable conditions. In the middle east it's used for cooling (obviously) while in cold places such as Europe, it's used for heating.

* AC is a short form for "Air Conditioning". Some people mix up between AC & A/C. A/C means "Alternate Current".

* From the cycle, we can see that low-pressure gas is compressed into high-pressure gas. The refregirant cools down to its liquid form and passes through the expansion valve which causes it to evaporate into a cold low-pressure gas. Heat is absorbed by the refregirant thus cooling the metal fins. A built-in fan blows air on to the cold metal fins causing room temperature to cool down.

Monday, 11 February 2013

Heating Systems

Heating Systems in UK

In the UK, various heating methods are provided with minimum cost. Gas is widely used in the UK as a heating method. A gas-fired boiler heats the water and to provide heat through radiators.

A more expensive method to heat is electricity. This involves night storage heates. These use electricity to heat special retaining-heat bricks which will keep homes warm for the day.

In some remote areas where homes are short of mains gas or areas where no main gas is provided, they can always tend to use LPG (Liquid Petrolium Gas). Like the mains gas, it heats the water and provides heat through radiators. Unlike the mains gas, LPG comes in a tank which a person has to buy and could be expensive.

Similar to LPG, rural areas of the country use oil instead. It's probably the same process. Oil-fired boiler heats the water and then the water provides heat through radiators. The oil-tank can be stored above the ground as well as underground.

People can always consider renewable heat by means of solar-energy. It doesn't only generates its own energy but it also reduces carbon print. Renewable sources of energy are very much recommended and people who are less ddependent on sources of energy such as gas and oil are most likely to prefer using these renewable sources.

To know more about how heating systems work in cold countries, watch:-

Thursday, 7 February 2013

Types of Robots

Types of Robots in Car Manufacturing Industry

What is a robot?

A robot is a mahcine which resembles a human being (in a way) and is capable of carrying out a complex series of action.

Coming to car industry, what are the various types of industrial robots used in car manufacturing industry.

Articulated Robots: These kind of robots are greatly flexible with rotary joints. They are used to inspect areas with assembled structures. It is also ued for assmebly, wielding, weld sealing and spray painting.

Cartesian Robots: These are used for pick and place operations, assembly, handling machine tools and arc wielding. They are also called as rectangular co-ordinate robots.

Cylindrical Robots: These kind of robots operate in a cylinder-shaped space. They have a least one rotary joint and at least one prismatic joint. They are used to handle products at die-casting machine, handling machine tools and spot wielding.

Parallel Robots: These kinds of robots have multiple arms each of one has three concurrent prismatic joints. They have large working envelope but are difficult to program and control.

SCARA Robots: SCARA stands for 'Selectively Complaint Arm for Robotic Assembly.These are cylindrical and have two parallel joints. They are also used in pick and place work and assembly operations.

Spherical Robots: These have two rotary joints and one prismatic joint. They are used to handle machine tools and arc or spot wielding.

How Robots Work in car Manufacturing?

To make a robot work, a computer program is installed on its controller computer. This provides a set of precise instructions--based on geometry and carefully timed--that tells the robot where to place things, how to rotate them, where to weld and how to perform all of its other functions. Robots do not think for themselves, and must rely on humans to provide instructions. Robots also can work in more extreme environments on their own, or they can work alongside humans, assisting them in their day-to-day jobs--such as moving or rotating a car so humans can work on parts of it that would normally be difficult to reach

See more about robots in car wheel manufacturing:-

Read more:-

* http://www.globalspec.com/learnmore/manufacturing_process_equipment/manufacturing_equipment_components/robots_robotic_accessories/industrial_robots

* http://www.ehow.com/about_4678910_robots-car-manufacturing.html

Subscribe to:

Comments (Atom)

.png)

.jpg)